Innovation is a customer-driven process and ValvEngineering has always pleased to develop tailor-made solutions to specific or unusual applications

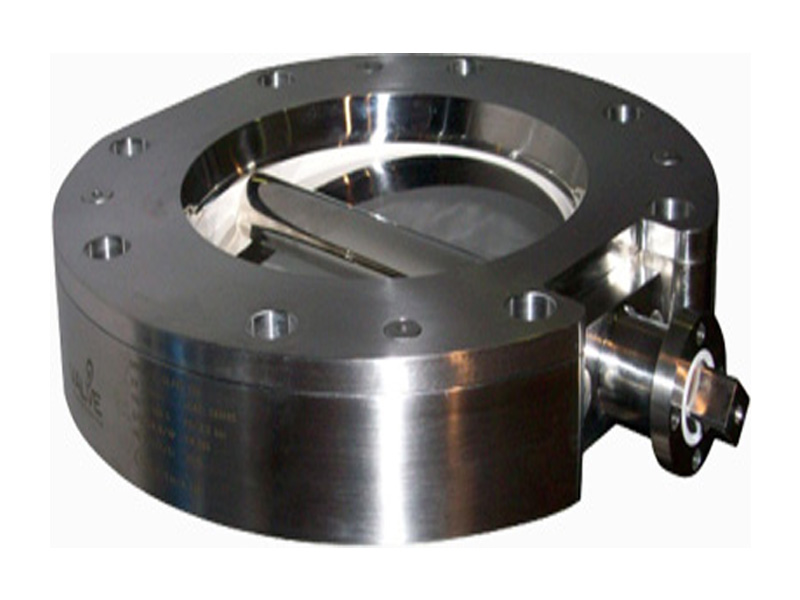

DN50 HC22/Fluoropolymer®

The Requirement

For the outlet of a Hastelloy Oyster Samplemaster valve, customer required DN50 butterfly valve with white FDA compliant perluoroelastomer seal – wetted parts HC22. Mount via 2″ tri-clamp.

We were unable to find such a high specification valve on the market and so we produced our own, which is now available for sale to other customers with similarly demanding requirements.

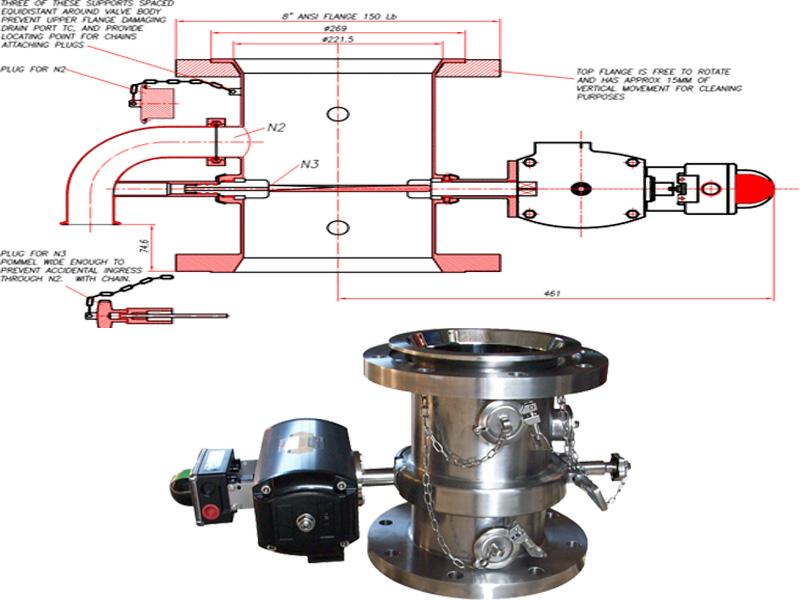

Draining Valve

The Requirement

This valve was designed and built for one of our clients in Ireland. The brief was for a valve which could be used in a system with regular wash downs and that would permit the system to drain right down to the level of the butterfly leaf.

What we delivered

A valve was produced with a drain through the short trunnion and a series of removeable plugs. Just to make matters more complicated still, the flanges on the inlet and outlet weren’t exactly aligned so the top mating flange had to be made “floating” so as to be able to match the bolt holes.

Du Pont Crop Protection

The Requirement

A manually operated valve with TC outlet, a shaped collar to take a flexible pipe on the inlet, the possibility of locking the valve closed by means of a padlock and a proximity detector for the open position.

Flowmaster Valves with Conical Transitions

The Requirement

Oyster Flowmaster dosing valves DN250 size but that would fit into a line via 12″ tri-clover clamps.

What we delivered

C10334

The solution was to build a valve with a built-in conical transition 12″ to 10″

Compact series Flowmaster Valve with ANSI flange connections

The Requirement

Oyster Flowmaster dosing valve DN150 with flange connections to ANSI #150 6” flanges

What we delivered

Oyster Flowmaster dosing valve DN150 with custom halfbodies with adaptation to flange connections machined from solid